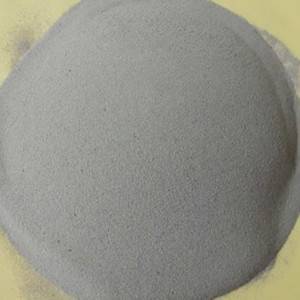

Refractory Cenospheres Ash Hollow Microspheres

Refractory Cenospheres Ash Hollow Microspheres

Hollow Ceramic Microspheres,Ash Cenosphere

low density 0.35-0.45 g/cc

210-850um 300um 150um 100um

Hollow silica-alumina microspheres (cenospheres) are recovered from fly ashes formed at coal-fired thermoelectric power stations (TEPS).

1.The properties of microspheres recovered from fly ashes are similar tomicrospheres industrially produced from melts,and much (several fold) cheaper than industrially produced ones.

2.The shape of Cenospheres is almost spherical, their surface is smooth, and their diameter is from 20 to 500 microns.They contain gaseous phase including mostly nitrogen, oxygen, and carbon oxide.

Benefits of Cenosphere

Reduced Raw Materials Cost Improved Flowability

Reduced Resin Demand Improved Insulation Values

Reduced End Product Weight Resistant to Resin Absorption

Specifications of Cenosphere

Chemical Property

|

Al2O3 |

SiO2 |

Fe2O3 |

CaO |

MgO |

K2O |

Na2O |

TiO2 |

|

25-35 |

50-65 |

2.0 |

0.2-0.5 |

0.8-1.2 |

0.5-1.1 |

0.03-0.9 |

1.0-2.5 |

Technical Property

| Grade No. |

TS-(20-70) |

|

|

Particle Size |

20-70mesh |

|

| +20mesh | 0.00 | |

| +30mesh | 3.60 | |

| +70mesh | 86.80 | |

| -70mesh | 9.60 | |

|

Floating Rate% |

>95 | 96.4 |

|

Bulk Density g/cc |

<0.38 | 0.352 |

|

Moisture% |

<1 | 0.36 |

More Products to Choose:40mesh 50mesh 80mesh 100mesh 150mesh or customized.

Applications of Cenosphere: Foundry&Refractory,Ceramics,Oil Manufacturing,Paint/Coatings,Building/Construction,Plastics,Automotive.etc

Packing: 20kg 25kg kraft paper bag,500kg,600kg big bag or as per customer’re request.