High Insulating Cenospheres for Paint Coatings

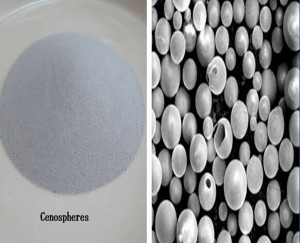

Cenospheres are unique free flowing powders composed of hard shelled, hollow, minute spheres. A small proportion of the pulverised fuel ash (PFA) produced from the combustion of coal in power stations is formed as cenospheres.

The main characteristics are:

•Hollow spheres with spherical morphology.

•Particle sizes ranging from 5 to 500μm in size.

•Ultra low density.

•Low thermal conductivity.

•High particle strength.

•Resistant to acids.

•Low water absorption

The main application in that of an inert filler. With a density lower than water (typically 0.6 – 0.8) cenospheres provide up to four times the bulking capacity of normal weight fillers.

Benefits:

A lower density compared to conventional fillers providing opportunities for weight reduction

Improved flow characteristics attributable to the spherical particle shape

Reduced shrinkage

Low oil (resin) absorption

Good chemical resistance

Increased hardness, scratch and abrasion resistance

Good thermal characteristics (lower specific heat capacity)

High compressive strength

100% recycled

Usage :

1.Cementing: Oil Drilling Mud & Chemcials,Light Cement Boards,Other Cementious Mixes.

2.Plastics: All types of Moulding,Nylon,Low Density Poluethylene and Polypropylene.

3.Construction: Speciality Cements and Mortars,Roofing Materials.Acoustic Panels,Coatings.

4.Automobiles: Fabrication of composite polymeric putties.

5.Ceramics: Refratories,Tiles,Fire Bricks.

6.Paints and Coating: ink,bond,vehicle putty, insulating, antiseptic, fireproof paints.

7.Space or Military: explosives,invisible paints for planes,ships and even soldiers,heat and compression insulating compounds,deep-water submarine.