-

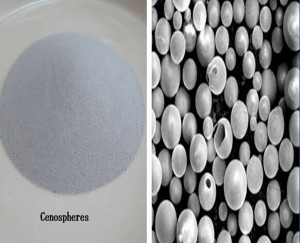

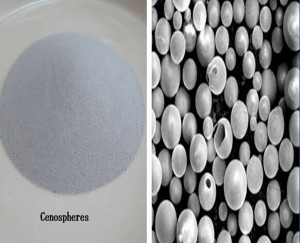

100micron Ceramic Microsphere/Cenospheres for Paint Coatings

Paint Additives Cenospheres

Hollow Ceramic Microspheres for Paint Coatings

100mesh 150mesh

-

Cenosphere/Hollow Ceramic Microspheres

Cenosphere/Hollow Ceramic Microspheres

20-70mesh 40mesh 50mesh 60mesh

80mesh 100mesh 150mesh.etc

Color: light gray to offwhite

Use: Foundry,Refractory,Constructions,

Oil Drilling,Paint Coatings,Plastics,Automobile -

Cenosphere or Hollow ceramic microspheres paint additives

Cenosphere are lightweight, inert, hollow, nonmetallic spherical materials, composed largely of silica (SiO2) and alumna (Al2O3) compositions of Cenospheres are similar with glass and ceramic.

1.Those hollow glass particles have also been called hollow ceramic spheres and micro spheres.

3.Due to their unique combination of spherical shape, high strength in compressing, good sound and thermal insulation, Cenospheres are utilized as a high performance filler material, that can replace other mineral filler.

Cenospheres are extremely free flowing powder composed of light shelled, hollow, small spheres. They have ultra low density, nonpoisonous, corrosion-resisting, thermal stable, high particles, strength, good insulating, sound isolating, low water absorption low thermal conductivity that are extensively used in the rubber equipment of glass fiber reinforced plastic, polyester, plastic as filler.

Cenospheres also are utilized for coating, paint and oil industry. Cenospheres are not only can reduce the weight of end products and cost but also increase the strength.

Hollow Sphere, 15 – 300 μm in diameter and are spherical, hollow. Due to the good flow ability, lightweight, Cenosphere can be used as filler materials.

Low Bulk Densities. Cenospheres bulk densities are 0.35 – 0.45 g/ cm3, provide up to four times the bulking capacity of normal fillers. They can greatly reduce cost of products, resin demand and weight of the end products.

Low-cost.

Cenospheres are 300% less expensive than man-made hollow glass sphere.

High Compressive Strength. The shell thickness of Cenosphere is about 10% of the radius. Their inside of the shell consist mainly of CO2 and N2. Due to the above spherical shape, Cenospheres can produce higher compressive strength.

Low Thermal Conductivity.

Good Sound Isolating

Good Insulation. Cenospheres conduct very little electricity and are ideal insulators used for making many electricity device.

Stability in Chemicals. The alumino-sillicate shell is resistant to water, any organic solvents, acids or weak alkalis. Like most glasses, Cenospheres are not resistant to strong alkalis.

Thermal Stability. Their thermal stability in temperature exceeding 1450C.

Non Inflammable.

Resistant to Water.

Low Shrinkage. Cenospheres are one of the few products in the filler industry today that can meet the requirements for low shrinkage. Cenospheres can reduce shrinkage when utilized in high volume loadings.

Apperance:

Size( μm ) 20-500 Shape Spherical Color Grey,White Applications:

Ceramics:

Refractories, Castables, Tile, Fire Bricks, Aluminium Cement, Insulating materials, Coatings.

Plastics

BMC, SMC, Injection Molding, Moulding, Extruding, PVC Flooring, Film, Nylon, High Density Polyethylene, Low Density Polyethylene, Polypropylene.

Construction

Speciality Cements, Mortars, Grouts, Stucco, Roofing Materials, Acoustical Panels, Coatings, Shotcrete, Gunite.

Recreation

Marine Craft, Flotation devices, Boling Balls, Surf Boards, Kayaks, Golf Equipment, Footwear, Lawn & Garden Decor.

Automotive

Composites, Under coatings, Tires, Engine Parts, Brake Pads.

Energy and Technology

Oil Well Cements, Drilling Muds, Industrial Coatings, Grinding Materials, Aerospace Coating & Composites, Explosives, Propeller Blades.Paint/Coatings

Non-slip Industrial Paints Marine Non-slip Paints Tennis Court Paints

Corrosion Resistant Coatings Textured Paints Thermally Insulating Coatings Anti-condensation Coatings

Building/Construction

Spackel

Crack Fillers

Joint Fillers

Stuccos and Renders

Cement Boards

Concrete Repair Mortars

Tile Adhesives

Ceramic Tile Adhesives

Floor Levelling Compounds

-

Insulating Paint Additive Cenospheres

Cenospheres are unique free flowing powders composed of hard shelled, hollow, minute spheres. A small proportion of the pulverised fuel ash (PFA) produced from the combustion of coal in power stations is formed as cenospheres.

The main characteristics are:

•Hollow spheres with spherical morphology.

•Particle sizes ranging from 5 to 500μm in size.

•Ultra low density.

•Low thermal conductivity.

•High particle strength.

•Resistant to acids.

•Low water absorption

The main application in that of an inert filler. With a density lower than water (typically 0.6 – 0.8) cenospheres provide up to four times the bulking capacity of normal weight fillers.

Benefits:

A lower density compared to conventional fillers providing opportunities for weight reduction

Improved flow characteristics attributable to the spherical particle shape

Reduced shrinkage

Low oil (resin) absorption

Good chemical resistance

Increased hardness, scratch and abrasion resistance

Good thermal characteristics (lower specific heat capacity)

High compressive strength

100% recycled

Applications of Cenosphere:

1.Cementing: Oil Drilling Mud & Chemcials,Light Cement Boards,Other Cementious Mixes.

2.Plastics: All types of Moulding,Nylon,Low Density Poluethylene and Polypropylene.

3.Construction: Speciality Cements and Mortars,Roofing Materials.Acoustic Panels,Coatings.

4.Automobiles: Fabrication of composite polymeric putties.

5.Ceramics: Refratories,Tiles,Fire Bricks.

6.Paints and Coating: ink,bond,vehicle putty, insulating, antiseptic, fireproof paints.

7.Space or Military: explosives,invisible paints for planes,ships and even soldiers,heat and compression insulating compounds,deep-water submarine.

-

Foundry Additives 20mesh Cenosphere/Hollow Ceramic Microspheres

Cenosphere/Hollow Ceramic Microspheres

Used for Foundry Refractory Additives

Particle Size: 20-70mesh

Color: Grey,off-white powder

-

Aluminosilicate Microspheres Cenosphere Fly Ash

Aluminosilicate Microspheres Cenosphere Fly Ash

Hollow Ceramic Microspheres/Ash Hollow Microspheres

Used for Paint Coatings,Oil Drilling,Foundry,Automotive..

-

High Insulating Cenospheres for Paint Coatings

Cenospheres are unique free flowing powders composed of hard shelled, hollow, minute spheres. A small proportion of the pulverised fuel ash (PFA) produced from the combustion of coal in power stations is formed as cenospheres. The main characteristics are: •Hollow spheres with spherical morphology. •Particle sizes ranging from 5 to 500μm in size. •Ultra low density. •Low thermal conductivity. •High particle strength. •Resistant to acids. •Low water absorption The main application in that of a... -

Lightweight Cenosphere Powder Ceramic Hollow Microspheres

Lightweight Cenosphere Powder Ceramic Hollow Microspheres

Lightening Agents Cenosphere Fly Ash Balloons

low density 0.35-0.45 g/cc

210-850um 500um 300um 150um 100um

-

High Insulating Cenosphere Microballoons,Ceramic Microspheres

High Insulating Cenosphere Microballoons,Ceramic Microspheres

Lightening Agents Cenosphere Fly Ash Balloons

low density 0.35-0.45 g/cc

210-850um 500um 300um 150um 100um

-

Thermal Insulation Cenosphere Coal Ash Microsphere

Thermal Insulation Cenosphere Coal Ash Microsphere

Cenosphere Fly Ash,Hollow Ceramic Microspheres

low density 0.35-0.45 g/cc

210-850um 500um 300um 150um 100um

-

Refractory Cenospheres Ash Hollow Microspheres

Refractory Cenospheres Ash Hollow Microspheres

Hollow Ceramic Microspheres,Ash Cenosphere

low density 0.35-0.45 g/cc

210-850um 300um 150um 100um

-

China Fly Ash Balloons/Floating Cenospheres

China Fly Ash Balloons/Floating Cenospheres

Hollow Ceramic Microspheres,Refractory Cenosphere

210-850um 300um 150um 100um

-

Cenosphere Floating Beads/Ceramic Microspheres for Coating

Carbon Cenospheres/Hollow Ceramic Microspheres for Oil Drilling

China Cenospheres/Carbon Microspheres for Oil Industry

Low density 0.85-0.90g/cc

300microns 420microns 500microns