100micron Ceramic Microsphere/Cenospheres for Paint Coatings

Alumino-silicate Cenospheres/Hollow Ceramic Microspheres for Paint Coatings

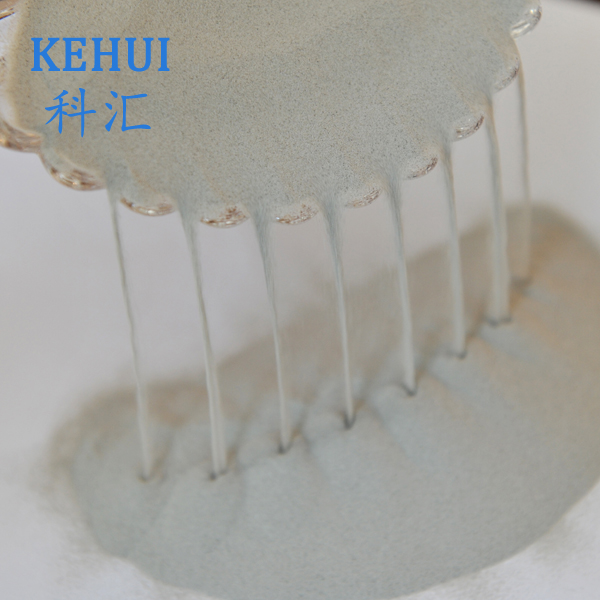

Cenosphere are light weight,inert,hollow speres of Silica and Alumina filled with gas which naturally occurs in the combustion of coal during the generation of electric power.The properties are same as manufactured sphered products.Thus it is also called as Glass Beads,Hollow Ceramic Sphere or Microspheres.

Size range from 20 to 500 microns with an average compressive strength of 3000+psi..

Colors range from white to light gray.

Main Advantages of Using Cenosphere for Paint and Coatings:

Spherical Shape Improved Flow and Leveling Hardness,Abrasion and burnish resistance

Good Thermal Insulation Corrosion resistance Chemical Resistance

Cost Reduction Dispersing Reduced Resin Demand Reduced Cost and VOC

Specifications of Cenosphere

|

Grade No. |

TS-100 |

TST-100 |

|

Particle Shape |

Hollow Spheres,Spherical Shape |

|

|

Particle Size |

-150µm 95%min |

-150µm 95%min |

|

Floating Rate |

95%min. |

95%min. |

|

Bulk Density |

0.33-0.45g/cc |

0.33-0.45g/cc |

|

True Density |

--- |

0.7-0.95 g/cc |

|

Moisture |

0.5%max. |

0.5%max. |

|

Thermal Conductivity |

0.054-0.095 |

0.054-0.095 |

|

Color |

Light Grey |

Light Grey |

|

Fire-resistant Degree |

1600-1700℃ |

1600-1700℃ |

Applications of Cenosphere

Cenopshere have been shown to improve performance,reduce VOCs,increase total solids and reduce costs in a wide range of applications,including:

High Solids Industrial Coatings Powder Coatings Coil Coatings

Heavy Duty Maintenance Coatings Marine Coatings Radiation-curable Inks & Coatings

Aircraft Coatings Primers Water Reducible Industrial Coatings Polymer Concrete